· Hersh Kshetry · Case Studies · 2 min read

Scalable MBR for New Township – Phased Modular Wastewater Plant

Engineered a phased membrane bioreactor (MBR) plant for a greenfield urban development, aligning treatment capacity with the community's growth from 1.5 MLD to 4.5 MLD

Overview

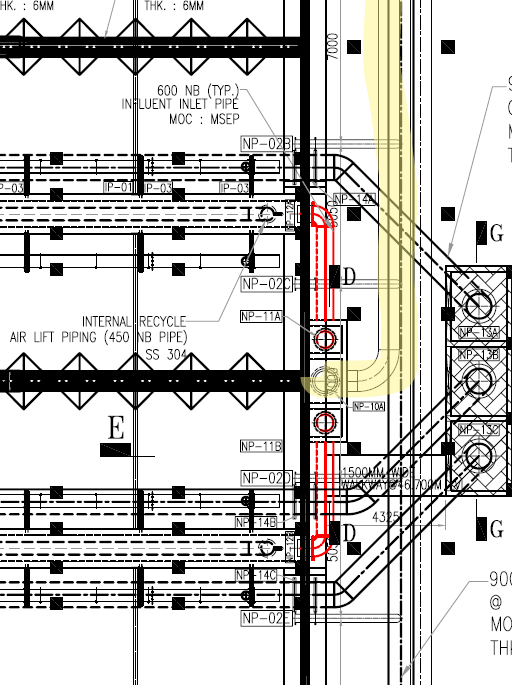

Engineered a phased membrane bioreactor (MBR) plant for a greenfield urban development, aligning treatment capacity with the community’s growth. The initial installation treats ~1.5 MLD, with civil works and piping designed to scale up to ~4.5 MLD in two future modules. This modular approach allowed the developer to invest in core infrastructure upfront (e.g. larger equalization tanks and headers sized for ultimate flow) while installing one MBR train initially and deferring additional trains until needed. The plant enables the new township to recycle its wastewater for landscaping and flushing from day one, and seamlessly expand capacity as population and water demand increase.

Technical & Strategic Insights

The design utilizes high-efficiency Teflon ultrafiltration membranes and robust biological process design to ensure reliable reuse-quality effluent even at the smaller Phase 1 scale. Key process units – from screening through disinfection – were over-sized for the ultimate 4.5 MLD flow, avoiding costly duplication in later phases. Meanwhile, the MBR bioreactor and membrane racks for Phase 1 were right-sized for 1.5 MLD to maintain optimal loading and operability.

Advanced automation features were incorporated: remote monitoring, data analytics for membrane fouling trends, and AI-based suggestions for aeration and cleaning optimization. This ensures even the initial module operates at peak efficiency with minimal staffing, a critical factor for a new township. The MBR system consistently meets stringent discharge and reuse criteria, positioning the development as a model for water sustainability.