· Hersh Kshetry · Engineering Insights · 6 min read

The AI Paradox in EPC - Why Agentic Workflows Will Create More Engineering Jobs, Not Fewer

How AI-driven project design and execution will unlock massive pent-up demand for capital projects, creating a Jevons paradox where engineering talent becomes more valuable than ever

One of the ongoing debates I have been following is the debate on the impact AI will have on the white-collar job market. Several opinions from prominent voices within the leading labs are warning of severe and rapid dislocation – among them Dario Amodei (CEO of Anthropic). As someone who has attempted to leverage AI in my workflow, it seems clear to me that – even in its current form – the models we have access to act as a significant productivity multiplier when leveraged correctly. But this does not mean that the demand for human labor (i.e. my time) has decreased; in fact, it has been the opposite – the list of things that I can do leveraging AI that were inaccessible prior to having the equivalent of a software engineer, business consultant, technical consultant, etc. at my disposal has grown so long that I find myself (paradoxically) with more work to do. Of course, the nature of the work is far different, but the same situation could play out across the job market – skills will be displaced, but not human labor – there will still be demand for people that can orchestrate AI agents to work towards a vision, use judgement to course correct, and sell what is produced to others.

Jevons Paradox

I believe the case for this phenomenon occurring in the EPC business as agentic engineering workflows diffuse through the industry is compelling. Oxford professor Bent Flyvbjerg’s extensive research documents what he calls the “Iron Law of Megaprojects”: over budget, over time, under benefits, over and over again. The statistics are sobering:

- Public Infrastructure: Average cost overruns of 20-80%, with some projects exceeding 400%

- Private Sector: Oil & gas megaprojects alone have accumulated $500 billion in cost overruns

- Schedule Performance: 70% of projects experience significant delays

- Benefit Realization: Actual returns typically achieve only 60-70% of projected values

This chronic underperformance has created a vicious cycle. As investors and governments factor in likely overruns, they:

- Add 30-50% contingency buffers to budgets

- Raise hurdle rates for project approval

- Shelve marginal but socially valuable projects

- Slow infrastructure modernization globally

The result is massive accumulation of unmet demand for capital projects worldwide. Using ChatGPT’s Deep Research, I attempted to quantify the value of this “pent-up demand” and estimate how increased efficiency in delivering projects (and increased reliability of cost and schedule estimates) could “pull forward” this demand and increase the labor requirement despite a lower labor intensity per-project.

Infrastructure Gap

- Current shortfall: $15-20 trillion through 2040 (business-as-usual scenario)

- True need: Likely far higher to bring global infrastructure to developed economy median standards

- Annual investment required: Would need to double from $3.3 to $4+ trillion to close both the current shortfall and meet the demand for modern infrastructure

Global Infrastructure Investment Gap Timeline

Cumulative shortfall in infrastructure investment through 2040 (trillions USD)

Annual Need: Growing from $3.3T to ~$4.4T by 2040

Current Spending: $2.5T annually (BAU)

Result: Gap reduced by ~4.5% through expanded investment capacity

Private Sector Capital Gap

- Industrial capacity shortfall: The private capital stock needed to meet global consumption at developed market levels likely represents multiples of the existing global stock

- Sectoral variations: Elastic sectors (electronics, pharma) vs inelastic sectors (utilities, basic materials)

The Dual Impact of AI on Project Economics

1. Labor Efficiency (The Obvious Impact)

- Engineering and project management hours reduced by ~25%

- But these services represent only 15-25% of Total Installed Cost (TIC)

- Net impact on project cost: ~5% reduction

2. Decision Intelligence - AI enables fundamentally better decisions across the project lifecycle:

- Design Optimization: AI can explore dozens of design alternatives vs. just a few manually, optimizing equipment sizing and configuration (assume 3-7% TIC reduction)

- Procurement Intelligence: Global supplier matching, price forecasting, and logistics optimization affecting the 40-60% equipment/materials portion of TIC (assume 5-10% TIC reduction)

- Schedule Optimization: Monte Carlo simulations and weather-adjusted scheduling reduce schedule slippage and assosiated costs (interest during construciton, contractor mobilization expenses) (assume 2-5% TIC reduction)

- Risk Mitigation: Better decision making reduces contingency needs (assume 2-5% TIC reduction)

Combined, AI-driven decision intelligence could reduce TIC by 12-27% - far exceeding the labor efficiency gains.

The Real Mechanism: It’s Not About Demand Elasticity

The traditional Jevons Paradox assumes high demand elasticity. But infrastructure demand is actually inelastic (0.06-0.52) - people need water, power, and roads regardless of price. So how does the paradox still apply?

Understanding the Dual Mechanism

For Infrastructure Projects:

- The bottleneck isn’t end-user demand but project bankability

- Currently 30-40% of needed projects fail investment thresholds due to execution risk

- AI doesn’t make demand elastic - it makes more projects investable

For Private Industrial CAPEX:

- Consumer goods often have elastic demand (>1.0)

- AI creates a double effect: production efficiency AND investment de-risking

- Competitive dynamics force investment to capture market share

How AI Expands the Project Universe

1. Risk Reduction (Primary for Infrastructure)

- Reduces cost overruns: 20-45% → 5-10%

- Improves revenue forecasting: ±20% → ±5% error

- Lowers WACC by ~100bps through reduced uncertainty

- Result: 15-20% of “unbankable” projects become viable

2. Volume Expansion (Primary for Private CAPEX)

- 10% manufacturing cost reduction → 8% price drop

- With elasticity >1: volume increases 10-15%

- Higher throughput justifies new capacity

- Result: 15-30% more projects in elastic sectors

3. Decision Intelligence (Both Sectors)

- Design Optimization: AI explores dozens more alternatives (3-7% cost savings)

- Procurement Intelligence: Global supplier matching, price forecasting (5-10% savings)

- Schedule Optimization: Weather-adjusted, risk-based scheduling, lowers delay related costs (interest during construction, contractor mobilization) (2-5% savings)

- Risk Mitigation: Better decision making and lower variance from proforma to actual costs reduces need for contingency (2-5% savings)

The Sectoral Jevons Paradox

The paradox strength varies dramatically by sector:

| Sector Type | Project Volume Increase | Engineering Hours/Project | Net Engineering Demand |

|---|---|---|---|

| Infrastructure | +15-20% (bankability) | -25% | +5-10% |

| Private CAPEX (Elastic) | +25-35% (volume + bankability) | -25% | +15-30% |

| Private CAPEX (Inelastic) | +10-15% (bankability only) | -25% | 0-10% |

Interactive Jevons Paradox Calculator

Explore how AI affects engineering demand through risk reduction (making unbankable projects viable) and cost reduction (driving volume in elastic markets)

Impact Breakdown

Project Volume Effects

Engineering Labor Paradox

Key Economic Insights

Infrastructure: Massive shortfall ($15-20T gap) means 40% of needed projects are unbankable. AI makes these viable through risk reduction, despite inelastic end-user demand (0.3 elasticity).

Private CAPEX (Elastic): Consumer goods (elasticity >1) see double benefit: 25% more projects become bankable PLUS volume growth from price-driven demand expansion.

Private CAPEX (Inelastic): Basic materials (elasticity 0.5) have limited price response but large capital shortfalls mean 30% of projects could become viable through risk reduction.

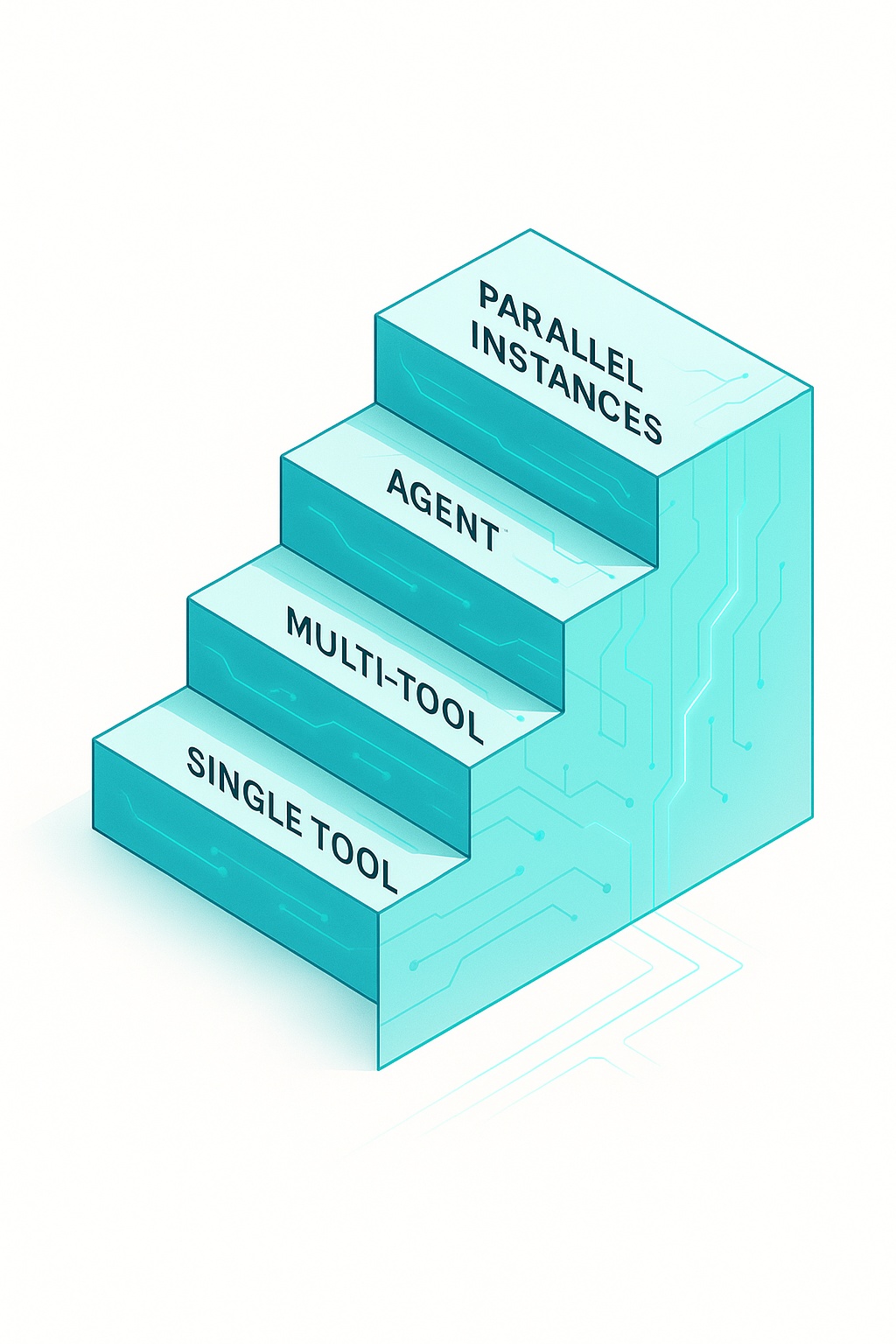

While demand for labor may increase, the transition won’t be smooth. Traditional engineering skills that can be automated (routine calculations, standard designs, basic documentation) will give way to roles requiring AI orchestration, judgment, and complex decision-making.

Not everyone will successfully make this transition. Just as manufacturing workers couldn’t all “learn to code,” not all engineers will adapt to AI-centric workflows. But the overall demand for engineering talent - particularly those who can effectively leverage AI - will likely increase as the addressable market for projects expands.

The key insight: AI doesn’t replace engineers; it changes what engineering means. Those who adapt will find more opportunities than ever before.