Fluids MCP Server

Hydraulics & Gas Calculations

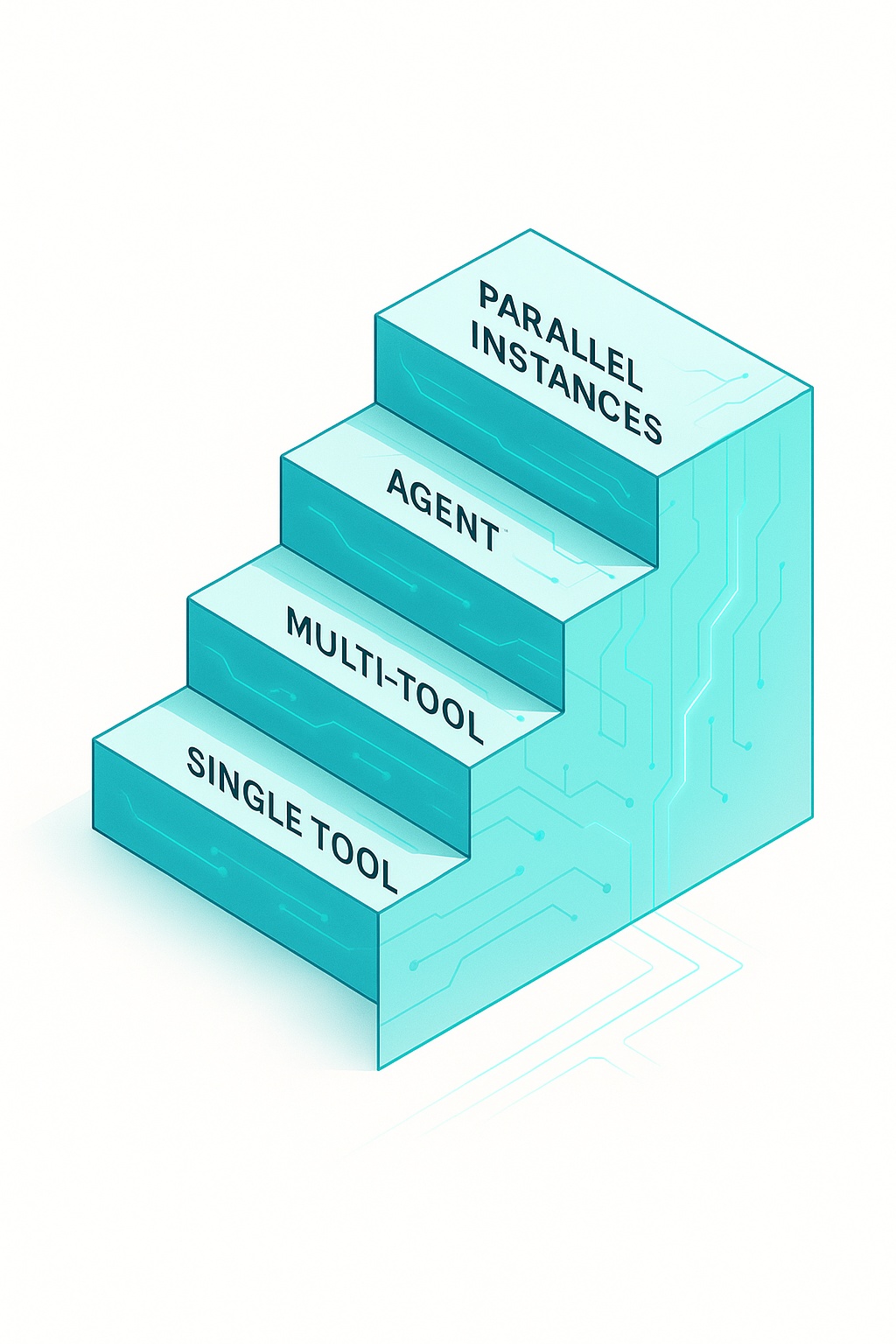

Comprehensive fluid mechanics server integrating multiple calculation methods for industrial applications. Agents can perform pressure drop calculations, size equipment, and analyze flow regimes with proper engineering units support.

Key capabilities: Liquid pipe pressure drop (Darcy-Weisbach with Colebrook-White), Gas flow methods (Weymouth, Panhandle A/B), Pump TDH and NPSHa calculations, Blower/compressor power requirements, Control valve sizing per IEC 60534, CoolProp integration for 120+ fluid properties at operating conditions, Parameter sweeps: Pipe pressure drop sweep (flow rate, diameter, length, pressure drop), Gas pipe sweep (inlet/outlet pressure, flow rate, diameter, length), Blower sweep (pressure ratio, flow rate, efficiency, inlet temperature)